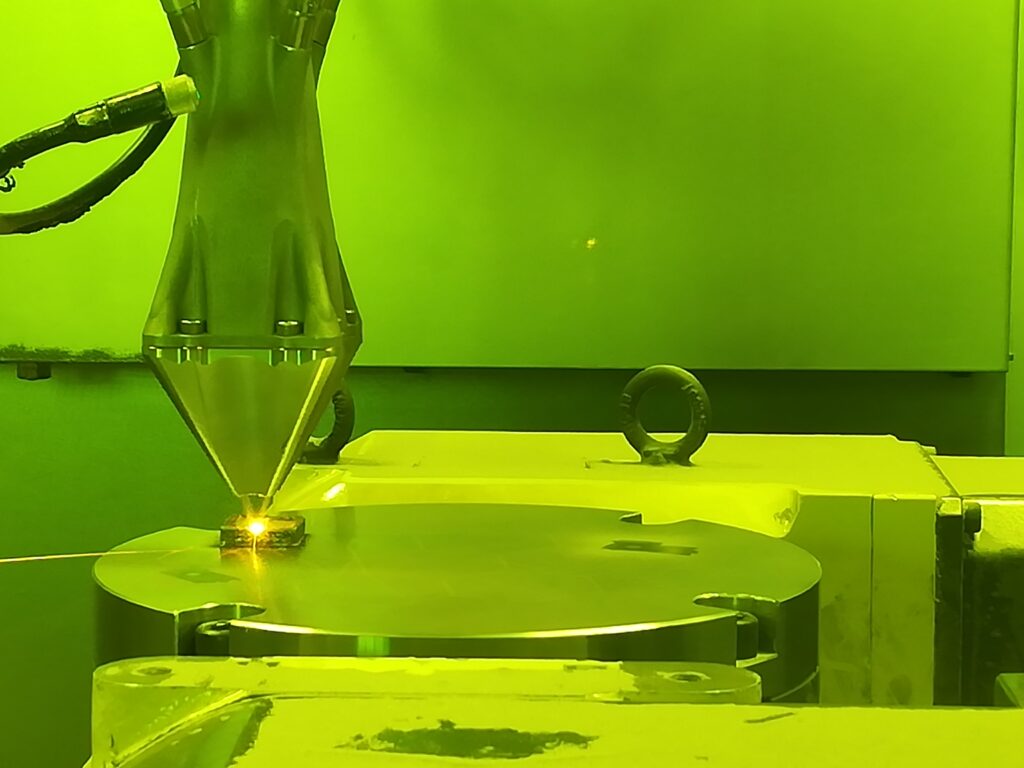

Goal full operation: the Competence Center at work on Direct Energy Deposition (DED) technology

Published on April 19, 2025

The Additive Manufacturing team, composed of members of CIM4.0 and its consortium members, just completed four days of training dedicated to the AM world, and the star machine was Prima Industrie’s Laserdyne 811.

In the spirit of continuing education that characterizes the Competence Center, the group tested itself with direct deposition technology (DED), the only one among additive technologies that allows projecting and simultaneously casting metallic material.

Within the Additive Manufacturing Pilot Line at CIM4.0, it will therefore be possible to experiment with this cutting-edge technology that enables new applications such as Repairing and Cladding. DED is attracting interest from the industrial world as it enables high production speed, low setup times and opens a door to new solutions.

The Competence Center thus began the process specialization journey through joint work with Prima Additive, laying the groundwork for testing innovative solutions on the pilot line through the Laserdyne 811.

A strategic collaboration, that between the Consortium and Prima Industrie, which aims to develop synergistic competencies at the service of companies to increase the competitiveness of the industrial sector. Prima Industrie, also a consortium member of the Competence Center, is a leading group in the development, production and marketing of laser systems for industrial applications, industrial electronics, laser sources and additive manufacturing solutions.