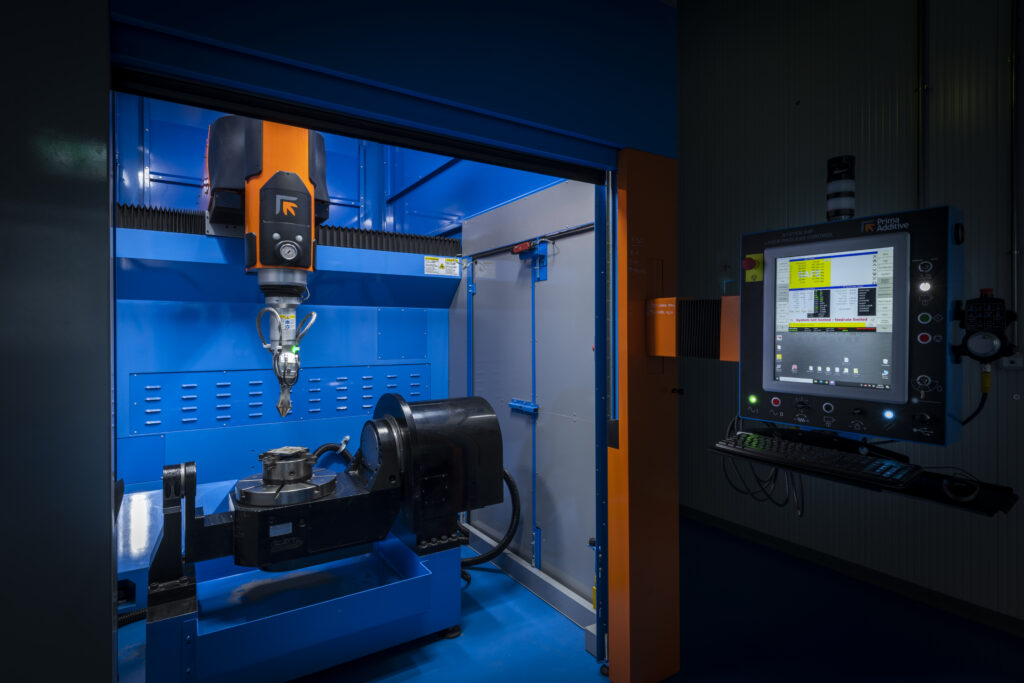

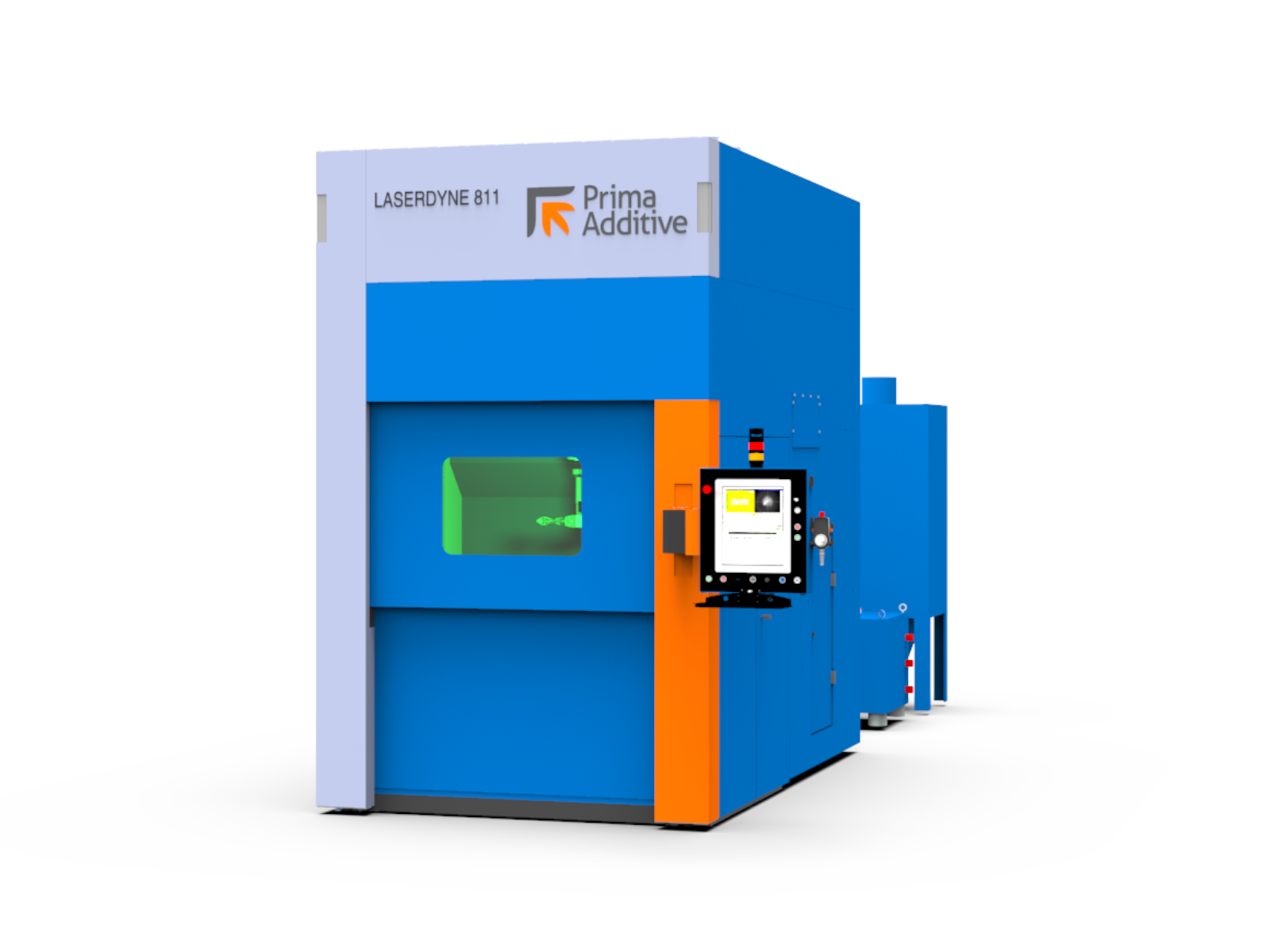

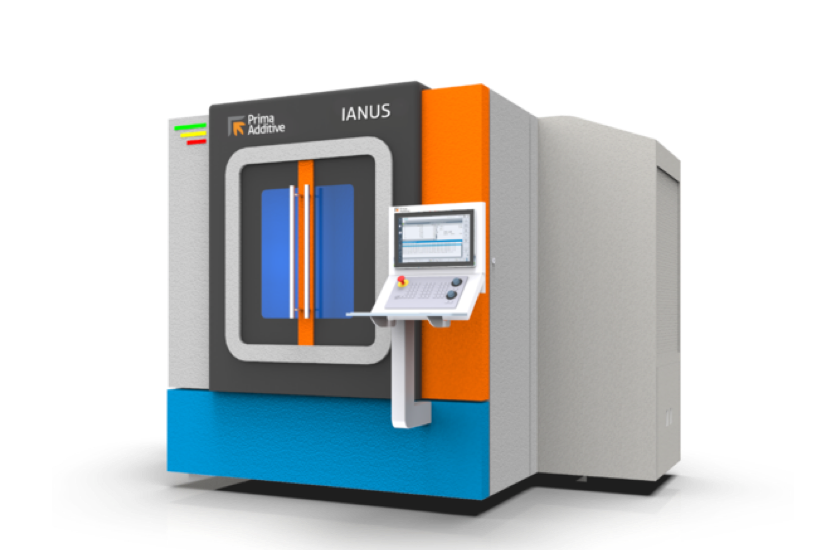

Additive Manufacturing Pilot Line

A state-of-the-art center dedicated to the industrialization of additive manufacturing

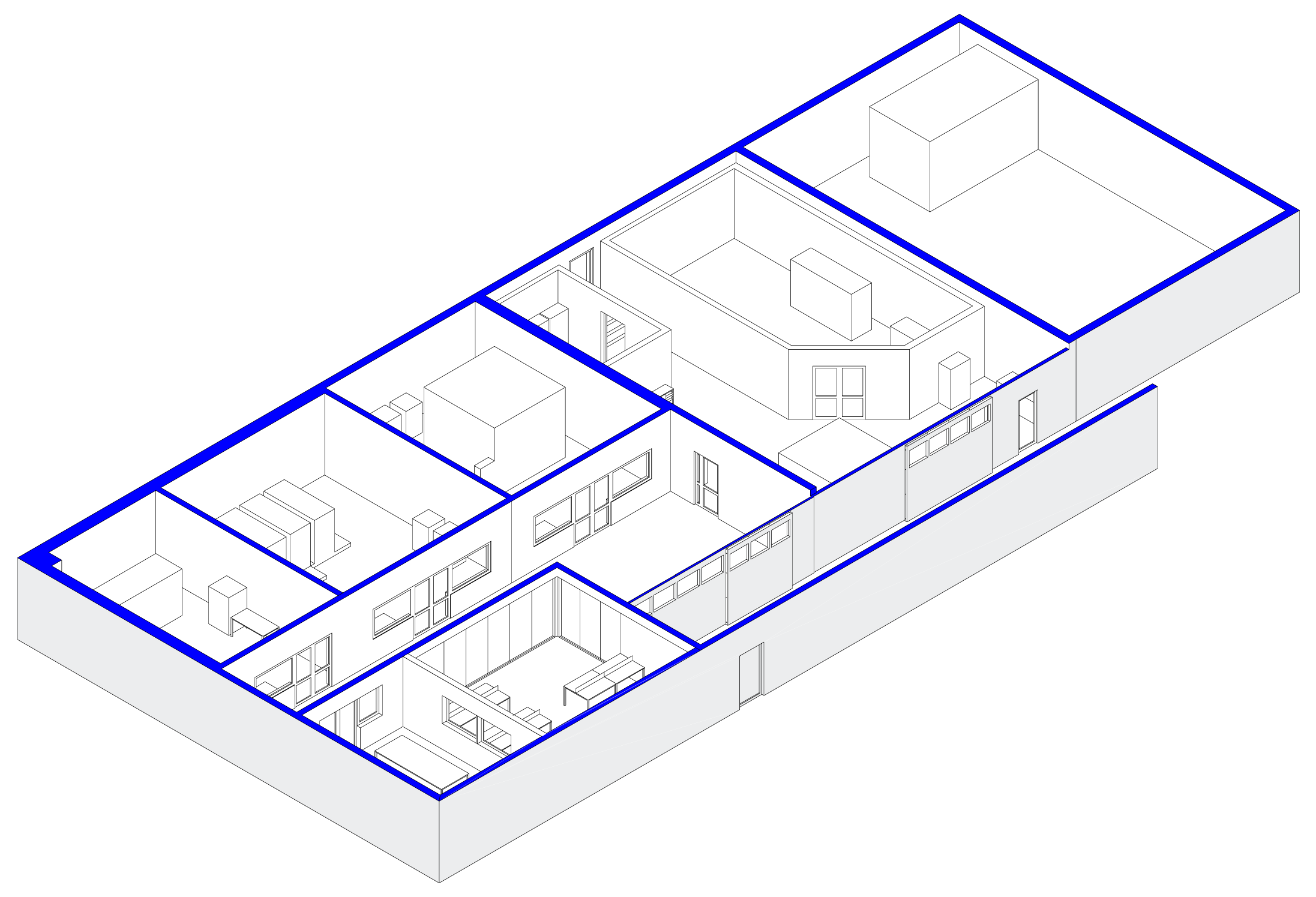

Visit the pilot line in VR

The Additive Manufacturing Pilot Line is waiting for you in virtual reality

Services

Additive manufacturing is accessible to all

Additive Manufacturing is a technology within the reach of Large, Medium and Small Enterprises.

CIM4.0 supports companies at all stages of technology adoption and bridges the skills gap through tailored services. We cover the entire value chain for AM processes, from feasibility study to 3D model creation, from printing to component inspection.

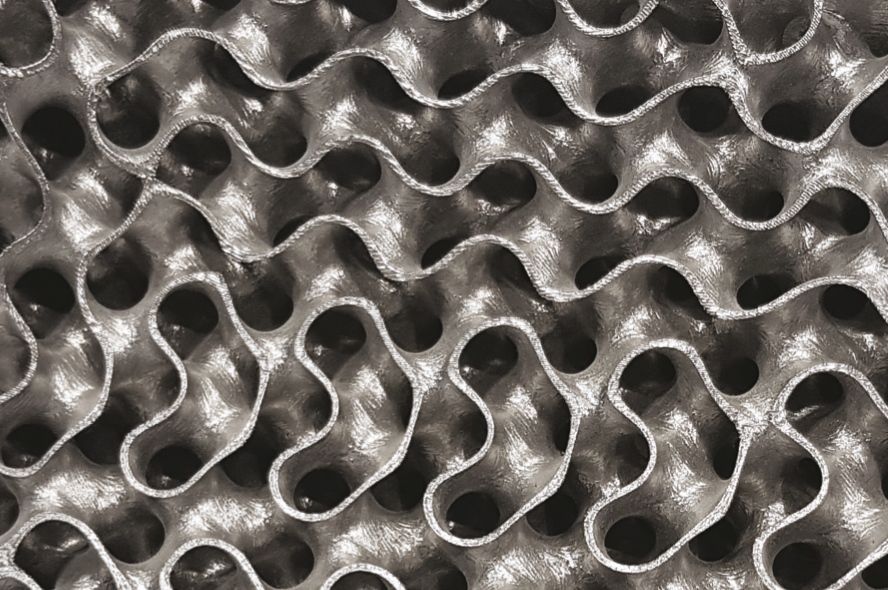

New product development

With a deep understanding of Design for Additive Manufacturing (DfAM) and the consortium partners’ experience in product engineering, CIM4.0 helps companies leverage AM to overcome the limitations of traditional manufacturing.

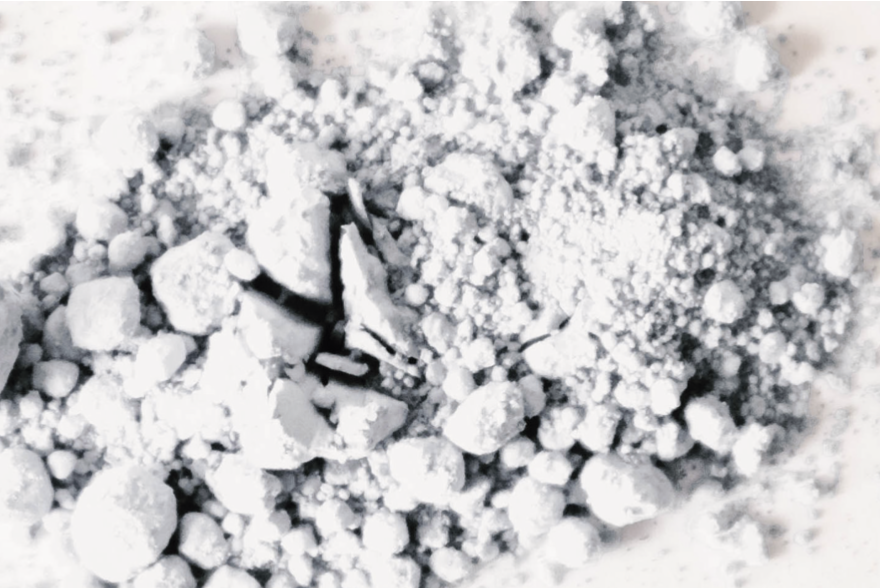

Process parameter optimization

The team develops custom process parameter sets to meet the needs of enterprises. In fact, by optimizing process parameters, it is possible to maximize functionality, production time, and post-process activities.

Product/process qualification

Thanks to the experience of the consortium partners, CIM4.0 supports the certification of the process and parts produced in Additive Manufacturing to meet the parameters of various standards, with particular expertise in automotive and aerospace.

Prototype and pre-series production

From consulting and design, material selection to process development, post-processing to final inspection. The entire process is managed, analyzed and monitored directly in the CIM4.0 pilot line.

Technology analysis

We perform technology analysis to understand costs, risks, and benefits by evaluating the suitability of a product made in AM. The goal is to chart a path for implementation taking into account the individual industrial reality.

Qualified training and workshops

AM is a rapidly evolving technology. With the Learning Hub and Academy, we transfer skills to operational engineers, designers, and process technologists through advanced training courses. Immersive, hands-on experiences that leverage Pilot Line assets to actually bring innovation into the enterprise.

Our spaces